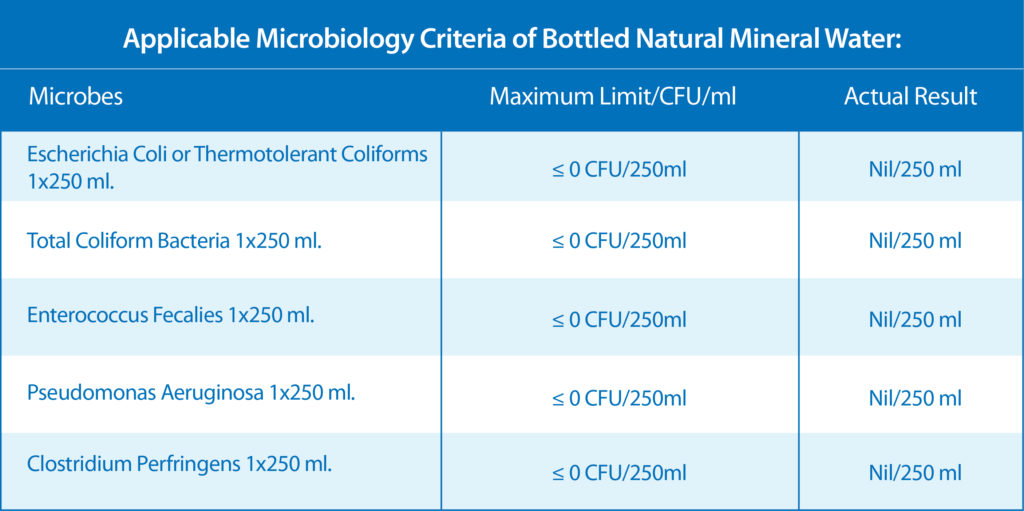

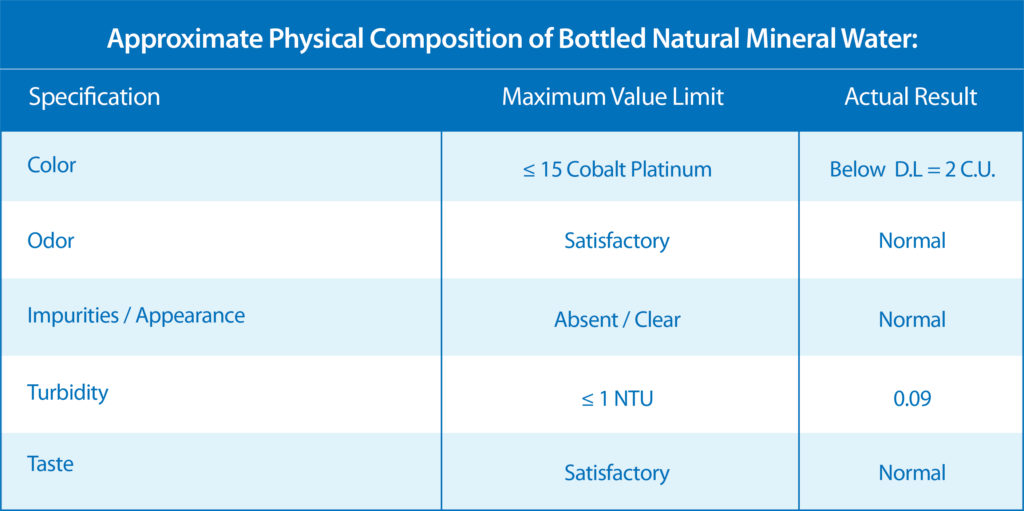

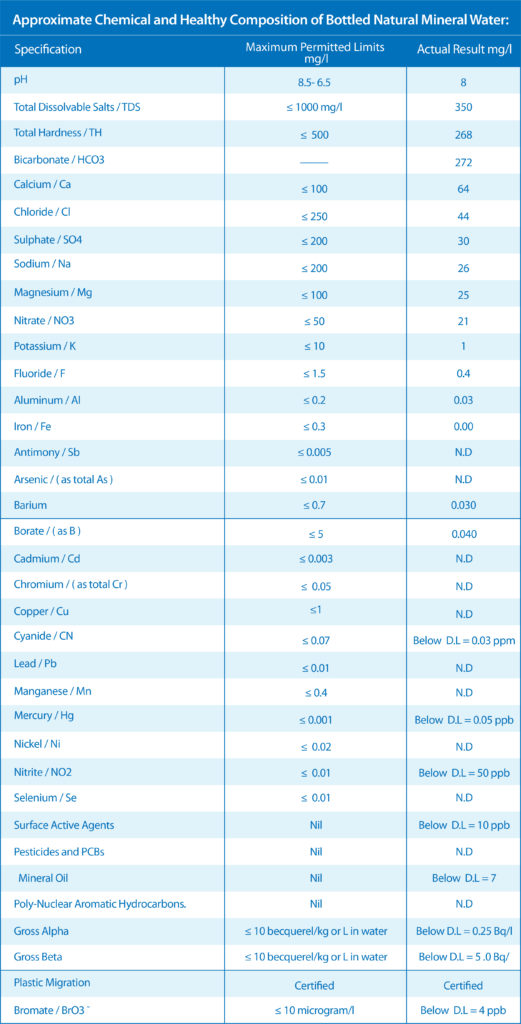

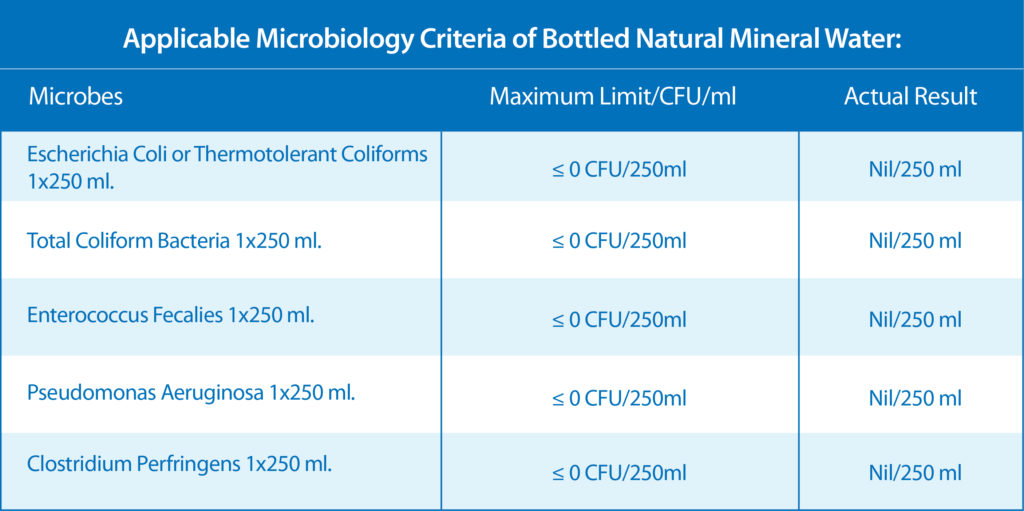

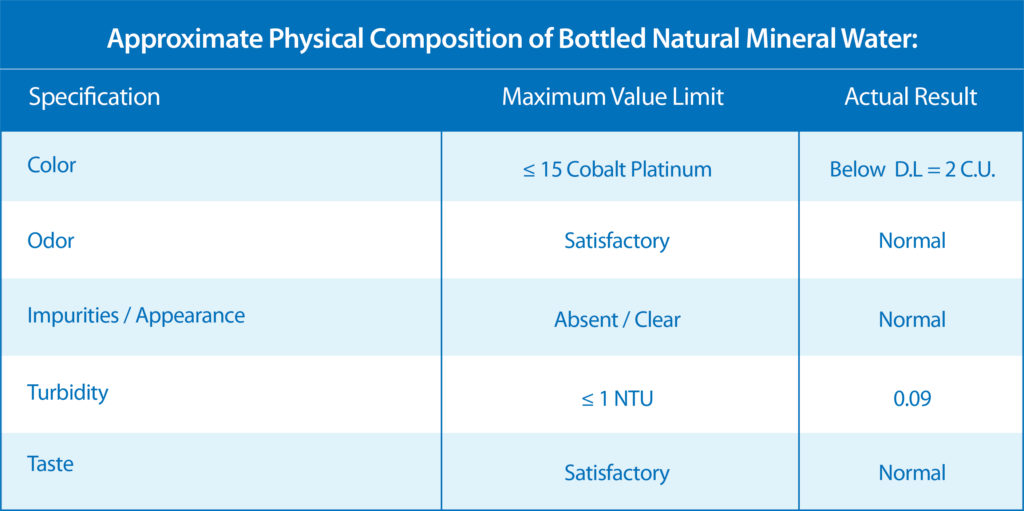

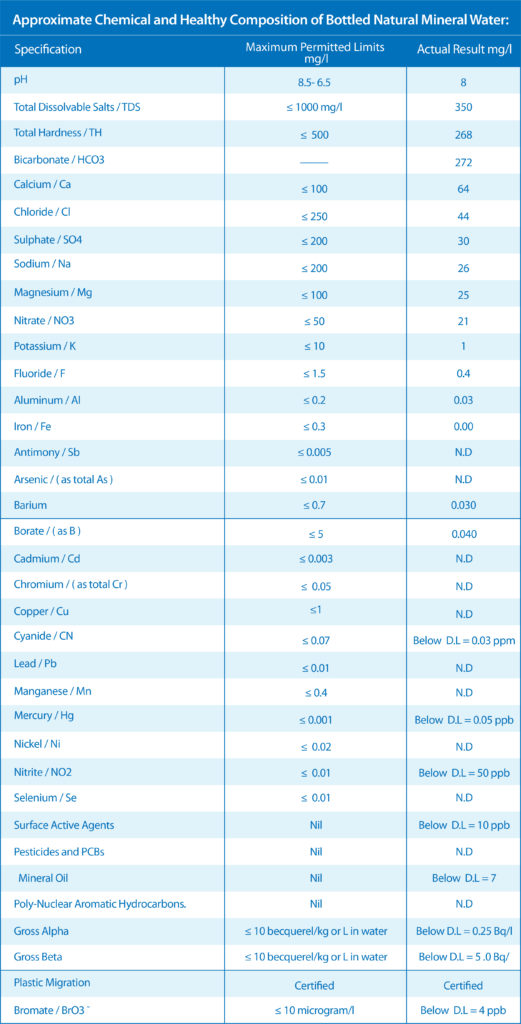

Bottled water quality parameters across the value chain

Quality at the source and the factory level is monitored and internally tested and externally verified. Our factory is equipped with its own

laboratory to conduct in-house tests to ensure product quality. At the factory level, microbiological, chemical, physical and sensory analysis are carried out to ensure safety and compliance.

VIVIANE Waters’ quality standards exceed those required by legislation in locally standards to conform the international standards and applied worthily the ISO22000:2018, which in turn manages and controls all process chain from receiving raw materials up to distribution the products.

As a leader in the bottled water sector, we apply the strictest standards, ensuring compliance with regulatory requirements and going well beyond them.

Our Quality Assurance Department is testing over 410 parameters along the entire manufacturing process to monitor water quality.

The specialized inspection center laboratory considered to be the most important sector in quick making decisions and adoption of production procedures based on work instructions and results accuracy of these comprehensive tests.

The laboratory includes the modern technology of microbiology inspection sector which represented by using membrane filtration technique; so that results are quick, accurate and closest to ideal.

Also, the chemistry sector is equipped with state-of-the-art measuring devices, able to detect compounds at the part per million (ppm) level.

These

tests are an important input for our Early Warning System to prevent and anticipate any potential risk.

Table below describes the applied criteria for all types of parameters in the company tests.